Chitosan powder, derived from chitin, a natural polymer found in the shells of crustaceans, has gained significant traction in various industries, from food and agriculture to pharmaceuticals. Its multifunctional properties, including its ability to act as a dietary supplement, a natural preservative, and a soil conditioner, make it a sought-after ingredient in many formulations. As demand continues to rise, selecting the right Chitosan Powder Factory becomes paramount to ensure quality and efficacy in the end products.

When searching for a suitable factory, several factors must be taken into consideration. Quality control, production methods, and sourcing of raw materials play crucial roles in determining the reliability of chitosan products. Furthermore, understanding the factory's capabilities for customization and adherence to industry standards can significantly impact the overall success of your endeavors. This article aims to explore the essentials of chitosan powder, its applications, and crucial guidelines for choosing the right Chitosan Powder Factory to meet your specific needs.

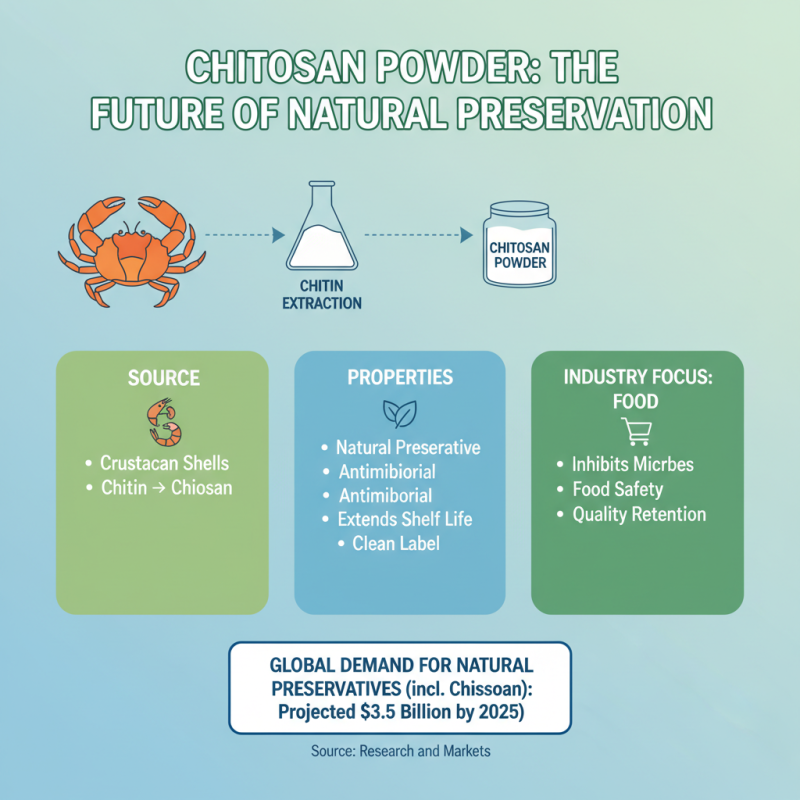

Chitosan powder is derived from chitin, a polysaccharide found in the shells of crustaceans like shrimp and crabs. This natural biopolymer possesses several remarkable properties, making it valuable in various industries. One of its most notable characteristics is its biodegradability, which makes chitosan an eco-friendly alternative to synthetic materials. Additionally, chitosan is known for its ability to form gels and films, enhancing its usability in pharmaceuticals, food preservation, and agricultural applications.

Another important property of chitosan powder is its biocompatibility and non-toxicity, which allows it to be used safely in medical applications, such as drug delivery systems and wound dressings. Furthermore, chitosan exhibits antimicrobial properties, which help in protecting products from spoilage and contamination. This has led to its implementation in the food industry for packaging and preservation, as well as in agriculture to promote plant growth and protect against pests. Given its diverse range of functionalities, understanding the properties of chitosan powder is crucial for selecting appropriate applications and formulations.

Chitosan powder, derived from chitin found in crustacean shells, is gaining traction across multiple industries due to its versatile properties. One of its primary applications is in the food industry, where it is utilized as a natural preservative. According to a report from Research and Markets, the demand for natural food preservatives, including chitosan, is projected to reach USD 3.5 billion by 2025, driven by the increasing consumer preference for clean-label products. Chitosan’s ability to inhibit microbial growth and extend the shelf life of food products makes it an invaluable component in maintaining food safety and quality.

In the cosmetics and personal care sector, chitosan powder serves as a moisturizing and film-forming agent in various formulations. A study published in the Journal of Cosmetic Science noted that chitosan enhances skin hydration and improves the overall texture of beauty products. The global skincare market, valued at over USD 130 billion in 2021, shows a rising trend towards products containing natural ingredients like chitosan, indicating its growing significance in cosmetic formulations. Furthermore, the pharmaceutical industry is leveraging chitosan for drug delivery systems, owing to its biocompatibility and biodegradability, which aligns with the growing emphasis on sustainable practices in healthcare. As per market analysis, the chitosan market is expected to witness a CAGR of 15% from 2023 to 2030, reflecting its expanding utilization across these diverse sectors.

When choosing a chitosan powder factory, several crucial factors should be considered to ensure you select a reliable supplier. First and foremost, it is essential to assess the factory’s certification standards and quality control measures. Look for certifications such as GMP (Good Manufacturing Practices) or ISO, which indicate that the factory adheres to international quality standards. A transparent quality assurance process can significantly impact the consistency and purity of the chitosan powder you receive.

Another key aspect is the factory’s production capacity and technology. Evaluate whether the factory has advanced processing equipment and scalable production capabilities to meet your demands. Understanding the factory's research and development capabilities can also be beneficial, as it may indicate their ability to innovate or customize products to suit specific applications. Lastly, consider the factory’s reputation within the industry; reviews and testimonials from other customers can provide insights into their reliability and the quality of their products, helping you make a more informed decision.

| Factor | Description | Importance Level |

|---|---|---|

| Quality of Raw Materials | The source and purity of chitin used can greatly affect the quality of chitosan. | High |

| Manufacturing Process | Different extraction methods can influence the final product's effectiveness. | High |

| Certifications | Look for ISO, GMP, and other relevant certifications to ensure product quality. | Medium |

| Customization Options | Ability to customize powder specifications to meet specific requirements. | Medium |

| Pricing | Competitive pricing can impact your overall budget for production. | Medium |

| Customer Support | Responsive customer service is crucial for addressing any issues. | High |

| Delivery Times | Timely delivery is important for maintaining your production schedule. | Medium |

When selecting a chitosan supplier, understanding quality standards and certifications is crucial for ensuring the product’s reliability and effectiveness. Chitosan, derived from chitin, is widely used in various industries, including dietary supplements, cosmetics, and agriculture. To maintain high quality, suppliers should adhere to specific standards such as ISO 9001 and GMP (Good Manufacturing Practices). These certifications indicate that the factory has a systematic approach to quality management and operational excellence, which significantly influences the consistency and safety of the chitosan powder produced.

Additionally, it is essential to consider any third-party testing and certifications that validate the purity and composition of the chitosan. According to industry reports, high-quality chitosan typically has a degree of deacetylation greater than 85%, which enhances its effectiveness in applications ranging from weight management to water purification. Suppliers that provide transparency through batch testing and comprehensive Certificates of Analysis (CoA) ensure you receive a product that meets your specific requirements.

Tips:

- Look for suppliers that have clear documentation of their quality control processes and third-party testing results.

- Evaluate whether the supplier can provide traceability for their raw materials, ensuring that the chitosan is sourced from sustainable and reliable sources.

When evaluating chitosan powder manufacturers, the first step is to assess the quality of their raw materials. High-quality chitosan is derived from crustacean shells and should display a high degree of deacetylation, purity, and low levels of contaminants. Requesting certificates of analysis can help ensure that the product meets established safety standards and does not contain harmful residues. Additionally, manufacturers should provide detailed information regarding their sourcing practices, as sustainable and ethical sourcing can be a significant indicator of product quality.

Another essential factor to consider is the manufacturer's production process. Look for companies that utilize advanced technologies and maintain stringent quality control measures throughout their manufacturing operations. Evaluating their certifications, such as GMP (Good Manufacturing Practices) and ISO standards, can further assure that they adhere to rigorous testing and quality assurance protocols. Lastly, customer feedback and reviews can provide valuable insights into the manufacturer’s reliability and the effectiveness of their chitosan products, helping you make an informed decision about which factory best matches your needs.